How to Make a Steerable Robot With Just One Single Motor

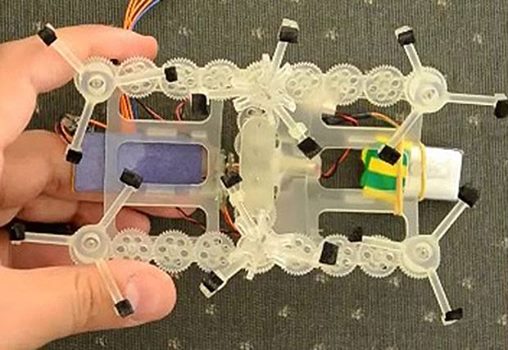

Imagine a little robot with six even little leggy wheel things that it uses to scurry around on the floor. Or, don’t imagine it, and just look at the picture above instead. This robot is called 1STAR, for “1 actuator STeerAble Robot.” Even though it has six legs, and it can controllably move and turn both left and right, it manages to do it with one single motor. Just one.

To clarify what’s going on here, 1STAR uses a single motor that only turns in one direction. With this motor, it can move itself forward, and it can turn. This is less of a trick and more about ingenious engineering and use of compliant materials.

If you didn’t get that explanation (I certainly didn’t the first time), here’s what’s going on. There are two key things: thing one is that the center pair of wheel leg things are compliant (springy), while the front and rear pairs are stiff. Thing two is that the single motor is able to finely pulse its acceleration.

The robot’s legs make contact with the floor in a tripod pattern. At a given point in time, one front and one rear leg are touching the floor, along with one middle (compliant) leg on the opposite side. If the robot accelerates, the compliant leg bends while the rigid legs don’t, and the robot will turn towards the compliant side, since the bending leg doesn’t move as far. If the acceleration of the robot remains constant, this will happen on each stride, and the robot will move forward. If, however, the robot only accelerates when the compliant leg on one side is touching the floor, and then decelerates when the compliant leg on the other side is touching the floor, it’ll turn in one direction. Switch up the acceleration and deceleration, and the robot will turn in the other direction. These changes in acceleration happen fast enough that you can’t see it as the robot moves, but as the video shows, the robot is easily capable of avoiding obstacles.

Obviously, you’re not going to get the most capable or controllable robot using this method, but you’re not going to be able to come up with anything much cheaper or simpler, either. Most of the structure looks to be 3D printed, so all of the cost is in the bits that you can’t print, namely, the battery, controller, and motor. Just having the one motor reduces the cost significantly, especially if you’re thinking about making a large number of robots, like you might want to if (say) you want to send a swarm of them to search for survivors of an earthquake.

“1STAR, a One-Actuator STeerAble Robot,” by David Zarrouk from Ben Gurion University and Ronald S. Fearing from UC Berkeley, was presented earlier this year at ICRA 2014 in Hong Kong, and mentioned again at the Stanford-Berkeley Robotics Symposium last week at Stanford University, which is why we’re writing about it now.

Date:10/28/2014

«« Return