4-D Printing Turns Carbon Fiber, Wood Into Shapeshifting Programmable Materials

Just as 3-D printers create objects that have three-dimensional characteristics, 4-D printers create objects that have four-dimensional characteristics, in that they include a dynamic component that causes their structure to change over time—relying on water, heat, or light to activate them.

Using a multi-material printer, it’s possible to generate objects with these properties all in one go. Such “programmable materials” may one day mean that you can buy flat-pack furniture at Ikea, take it home, and hit it with a garden hose while you watch it slowly assemble itself. We don’t even have to speculate: MIT is working on this exact thing.

To understand how a programmable material works, think about what often happens to a thin strip of wood if you get it wet: It warps, as different parts of the wood swell in slightly different ways. Usually, this is bad, because the warping is unpredictable and related to the type of wood, the patterns in the grain of that wood, how and where it gets wet, and so forth. If you could somehow predict the warping, though, you might be able to find a piece of wood that you could deliberately warp into a shape that you wanted, just by adding water.

This is not a thing that we can do with natural wood, but that’s fine, because we don’t need natural wood anymore. With 3-D printing, it’s possible to manufacture pieces of wood with whatever composition, thickness, and grain characteristics that you want, meaning that with a comprehensive understanding of how the material behaves, along with computer models, you can 3-D print a piece of artificial wood that’s been “preprogrammed”— using carefully constructed layers of various thicknesses and grain directions—to warp itself from flat into exactly the shape you want.

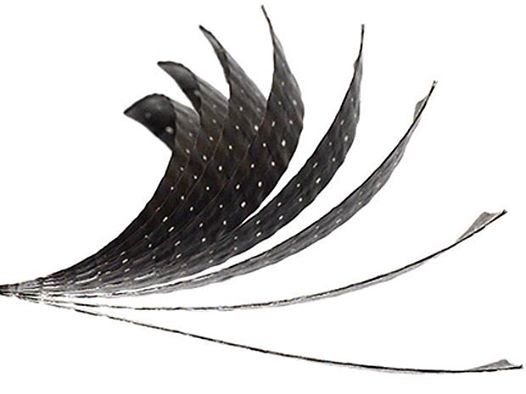

The MIT Self-Assembly Lab (under the direction of Skylar Tibbits) has been developing a variety of programmable materials, not just wood. The Lab’s also working on textiles (imagine a flat piece of cloth that turns into a cowboy hat whenever it starts to rain), along with slightly more exotic materials like flexible carbon fiber

Working closely with Carbitex, an advanced materials company with a radical new flexible carbon fiber technology, CX6™, we have developed a system to produce programmable carbon fiber material that can fold, curl, twist and respond to a variety of activation energies. By printing various materials within the flexible carbon fiber grain, we are able to promote local curvature when subject to heat, light or moisture. Programmable carbon fiber enables a wide range of applications from morphable airplane flaps to self-regulating air intake valves, adaptive aerodynamics, tunable stiffness structures and a variety of other dynamic applications. These capabilities were previously impossible or required expansive and complex robotics but are now feasible through programmable material transformations.

The big advantage of these programmable materials (besides the potential for easy furniture assembly) is that you can make things that move and react to their environment without having to introduce complex, expensive, heavy actuation systems and the electronics required to drive them. The aerospace industry is already interested in this sort of thing (Airbus is working with MIT on a jet engine air intake regulator), but Tibbits was willing to speculate to Fast Company about such things as self-lacing McFly sneakers from Back to the Future II. And that self-assembling flat-pack furniture? MIT is already talking with an unnamed furniture company (that may or may not be based in Sweden) about making it a reality.

Date:10/28/2014

«« Return